System design

GSN/FCU conducts fire management for each battery consisting of 2x35mm artillery guns (Annex 1). GSN/FCU is a fire management system based on an optoelectronic tracking device and equipped with a ballistics computer for path calculation and fire correction. GSN/FCU is mounted on a small trailer and has an autonomous electrical power group (Figure 2).

|

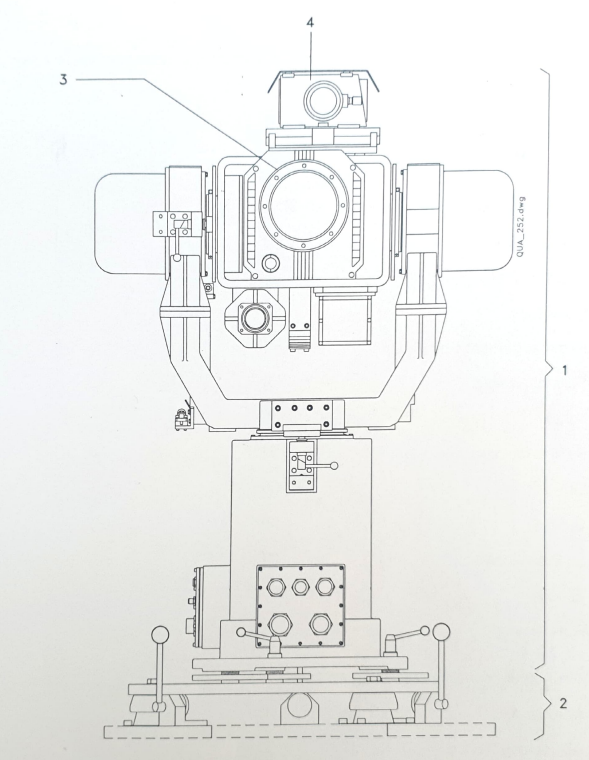

The Tracker Unit (TU), with laser telemetry and FLIR, is a platform controlled by a group of sensors (FLIR, Laser distance Meter) mounted to achieve target detection, tracking, video playback and telemetry. The FLIR sensor is capable of detecting small ambient temperature differences relative to a target; this is done by scanning objects that produce a thermal image. The LASER telemetry is used to measure the distance from the targets that are sensed and followed by the GSN-FCU FLIR Sensor. |

1. Trucker Mount; 2. Base; 3. FLIR Sensor; 4. Laser Rangefinder |

|

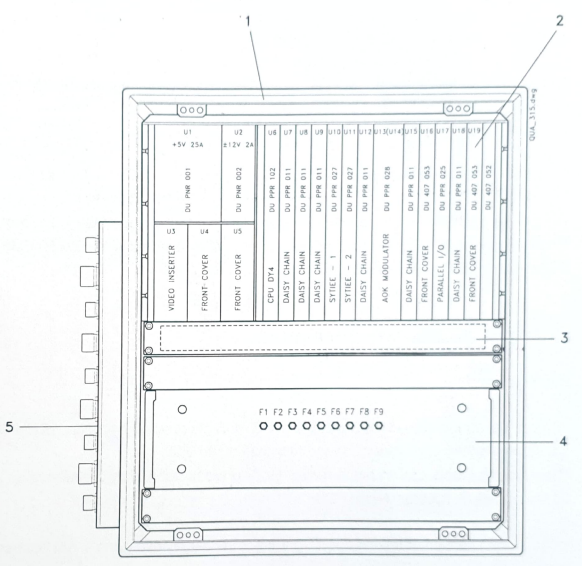

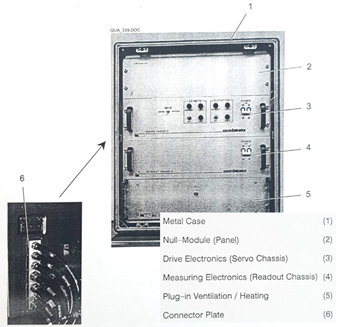

The Data Processing Unit (DPU) is the central computerized and control system of the FCU GSN. The DPU, together with a performance software program, performs the following main functions: - Collect target data via the sensor system; - Calculate the control data (azimuth and elevation) for the Tracking Unit; - Calculate the shooting data for the artillery pieces; - Controls the entire operating system. |

1. Metal Case; 2. Computer Electronics; 3. Fan Assembly; 4. Power Supply Distribution; 5. Connector Plate |

|

The Tracker Control Unit (TCU) performs the guidance control of the two axis Tracker Unit. The TCU performs also the task to send back to the DPU the information concerning the actual values of angular position and angular rate and furthermore the status of the sensors installed on the Tracker Unit and the Tracker Control Unit itself. |

|

|

Video Processing Unit (VPU) processes the analogue composite video signal (CVS) which originates in the FLIR sensor. The main task is to discern a target in the FLIR field of view and to determine the angular position of the target with respect to the optical axis of the FLIR sensor . The VPU performs the following functions: -it distinguishes the target from the FLIR field of vision; - it determines the angular position of the target, observing the optical axis of the FLIR sensor; - it evaluates and processes the pixels of the target image representing it in a digital image of the target. |

|

|

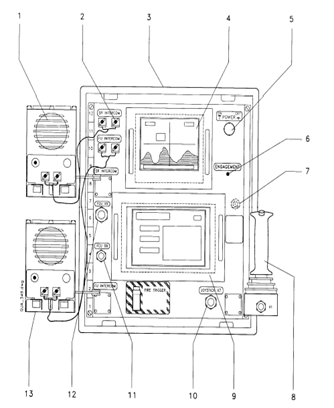

The Operator Control Unit (OCU) is contained in a metal box; it can be removed from the transport Trailer in order to operate remotely the GSN/FCU. It is equipped with the following main parts: - Video Monitor (it reproduces on a screen the image that the FLIR Sensor captures during target tracking and shows some operative parameters to the operator); - Touch Panel Display (it allows the Operator dealing with the main computer of the GSN/ FCU; the operator can set directly on the screen many different data, and can receive from the computer indications related to the current operations state); - Joystick (it allows moving the Trucker Mount of an amount proportional to the Joystick deflection); - Two Intercom stations (provide vocal communication with SHORAR-TCP and vocal communication with Digital Optical Sight and with the 35 mm Guns). |

(1) Search Radar Intercom Station; (2) Intercom connector; (3) Operator Control Unit Box; (4) Video Monitor; (5) Power ON/OFF Pushbutton; (6) ENGAGEMENT Lamp; (7) Buzzer; (8) Joystick; (9) Touch Panel Display; (10) Connector X7; (11) Connector X5; (12) Connector X6; (13) FU Intercom Station |

|

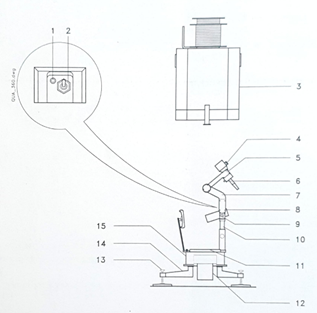

Digital Optical Sight (DOS) consists of a lower and a rotatable upper mount with the operator’s seat and the adjustable column. The DOS allows easy, fast and highly accurate acquisition of suddenly appearing targets. It is handled by an operator and is used for aerial surveillance and air designation/ acquisition in case of a surprising attack and at a relatively short distance. The operator can eye a visible target and assign it to the GSN/FCU with the following coordinates: - angle of the target associated with the physical position of the operator seat; - target elevation associated with the physical position of the sight-glass arm. |

(1) LED H1 DOS READY; (2) Toggle switch S2; (3) Covering hood; (4) Collimator; (5) Swivel arm; (6) Pushbutton S1 DOS ON TARGET; (7) Bracket; (8) Intercom station; (9) Locking bolt; (10) Adjustable column; (11) Seat; (12) Support; (13) Spindle; (14) Outrigger; (15) Housing |

|

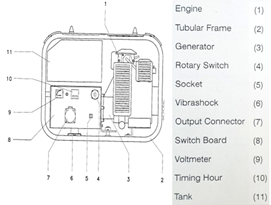

Power Supply Unit (PSU) is supplies the electrical energy required for operation of the FCU. It consists of a gasoline engine with a coupled asynchronous generator. The main technical characteristics are: -Type: asynchronous, single-phased - Output voltage: 230 VAC; - Frequency: 50 Hz; - Fuel used: unleaded petrol; - Average consumption: 1,5 l/h. |

|

|

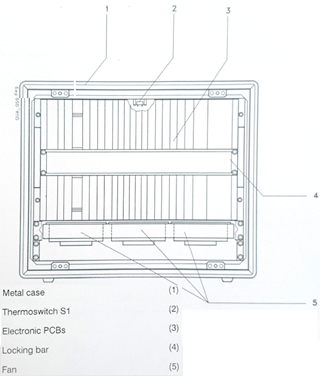

The Battery Unit (BU) holds four 12 V batteries. The batteries are connected in series to provide the 48 V system voltage. The battery charger unit (BCU) performs the following tasks: - AC/DC conversion; - charges the batteries; - controls the charging process in accordance with of the batteries used; - optimizes the charging process by controlling the charging voltage depending on the ambient temperature; - provides five relay outputs to the DPU. |

Battery Charger Unit (BCU) – (1); Battery Set (2); Power Distribution System (PDS) – (3). |